MATERIAL QC

MATERIAL QC

In the pursuit of achieving consistent particle size and well-blended materials, the tilting wet mill stands out as a convenient option for the efficient loading and unloading of materials. To accomplish this, the maximum ball grinding time can be extended up to 72 hours. Every batch of material undergoes a thorough screening process with a vibrating screen, ensuring precise control over potential irregular particles or impurities. This meticulous screening process guarantees uniform particle sizes in each batch, thereby ensuring the reliable and uniform production of high-quality materials.

BLANKS QC

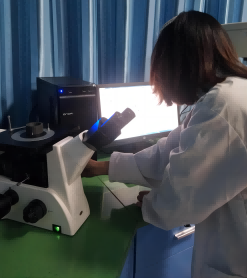

In the quality control process for blanks, sample pieces are meticulously crafted for each batch of raw materials. Subsequent monitoring and analysis cover a spectrum of performance parameters, including density, hardness, bending strength, porosity, metallographic structure, magnetic saturation, and more. The resulting data is systematically recorded, assigned a unique identification number, and archived for future reference, with a retrospective period extending up to 12 months. This thorough quality control ensures that the blanks meet stringent standards and adhere to the specified performance criteria.

SEMI-FINISHED QC

SEMI-FINISHED QC

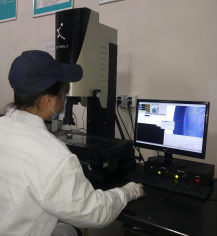

After the culmination of each stage in the production process, a rigorous inspection becomes essential to confirm adherence to the specified processing dimensions. To facilitate this, specialized dimensional inspection zones are designated at every stage of the process, ensuring meticulous scrutiny and strict adherence to precise size requirements. This systematic approach to quality control guarantees that the semi-finished products meet the exacting standards and dimensional specifications set forth in the production process.

FINISHED QC

After the finalization of the cleaning process, the completed product is transported to the designated inspection room for finished products. In this space, the staff conducts a meticulous and step-by-step examination, adhering to internal drawings that encapsulate the specific requirements. This comprehensive inspection is undertaken to ensure that the products align precisely with the expectations and demands outlined by the customer. This dedication to thorough quality control at the finished product stage ensures the delivery of products that consistently meet the highest standards.

Our steadfast dedication to quality remains resolute as we meticulously adhere to a rigorous inspection protocol. This all-encompassing process commences with the meticulous scrutiny of raw materials and seamlessly progresses through every stage of production. It culminates in the exhaustive examination of the final product, ensuring not only exceptional quality but also strict compliance with the most stringent standards. Our unwavering commitment to maintaining these elevated standards is the cornerstone that guarantees the delivery of products consistently exceeding customer expectations.